KGO Group offers a wide variety of chemical feed systems and equipment, primarily noted for our handling of dry bulk material; we also offer a wide range of standard and customized liquid feed systems. Liquid dosing is a significant part of our offering; our applications team works with clients to determine the best approach to meet your process needs within a pre-stated budget. This may include alternatives to pre-conceived or initial methods for applications that may not provide the desired results or not fit your budget.

We work to understand your requirements and review them with internal personnel, including engineering, mechanical, electrical and fabrication staff. This review is a critical part of taking on a project; the knowledge and experience of these teams play a role in how we address each application and prepare a win-win outcome for our clients.

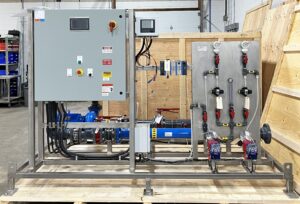

The chlorine system shown was designed to maintain a residual of 2 ppm in a medium-sized flow-through tank system for a small residential community. The recirculation pump runs continuously to and from the tank and supplies water to the Chorine Probe holder. We included fail-safe devices to guard against over and underdosing the system and ensure a constant recirculation flow rate.

Supply chain issues played a part in the design and delivery of this custom-built chlorine system; our Procurement and Project Managers worked together to provide solutions acceptable to our client in terms of delivery and price. The cohesiveness of our team members was key to bringing this project to completion and shipping on time and within budget.